The prestigious project of processing and landfill of 3000 tons per day of solid waste with the combination of various technologies such as bioreactor landfill [Anaerobic digestion] waste to compost, methane gas to power, RDF, Sanitary Landfill etc. The project will be one of the biggest engineered Bioreactor landfill projects in the country.

Objectives –

To control odor from solid waste and speed up bio-degradation of organic matter in the composting process by using MiCroBial Technologies product. This technology is treating about 200-500 tons of segregated organic waste material in composting process which is based on windrow composting technology. This organic material composed of kitchen wastes (food & market waste), oil, fats, grease, protein, carbohydrates, cellulose, other organic and inorganic substances coming from different areas of city due to incomplete bio-degradation of these substances mentioned above, its producing strong odor. Thus, it was necessary to develop fast organic matter degrading microbial culture/colonies during the process of composting with reduction in strong/bad odour.

MiCroBial Technologies Solutions –

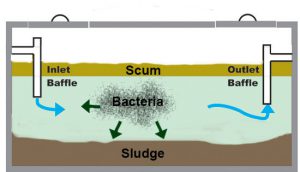

MiCroBial Odor is a natural bio-catalyst made via novel fermentative process that has been refined by microbiologist in India. MiCroBial Odor consists of selected consortium of bacteria and enzymes that degrade organic matter as carbs, proteins and fats. These microbes produces different types of enzymes as amylase, protease, lipase, cellulase etc. MiCroBial Odor works in both aerobic and anaerobic conditions as it contents aerobic and facultative microbes in waste water treatment.

Dosing Program

- Recommended Product MiCroBial Odor

- Volume of solid waste 490 tons of solid waste ( Single composting windrow)

- Product quantity required 2 kg for 500 tons of solid waste

- Fresh water required 200 – 250 liters of fresh water

- Application point Batch no 178 as MiCroBial Odor & 177 as Control Batch

- Mode of application Application thru tractor mounted jet spray

Implementation Protocol for the Application –

- 2 kg of MiCroBial Odor was mixed with 200-250 liters of fresh water.

- Solutions was mixed well with the sprayer & allowed it to stand for 15 mins for activation of microbes, after that, solution was sprayed/sprinkled evenly on the solid waste windrows in such a way that MiCroBial microbes/enzymes should come into contact with organic substrate (Solid Waste).

- With the application of 200-250 liters of mixture of MiCroBial Odor, moisture of compost should not be disturbed.

- Turning of composting windrow was done after 4th & 3rd days of cycle with regular interval till 28 days.

- All optimum condition was provided during application of MiCroBial Odor and normal procedure of composting process was done as per the composting technology. 6.

- Batch no 178 was taken for the “MiCroBial Odor” trial and batch no 177 was considered as “Control Batch” where no culture was used.

Observation During Trial –

- Significant Odor was controlled after application of MiCroBial odor observed on second day.

- Significant odor control was observed during 1 turning of 4 day after application of MiCroBial odor & no odor was

observed on 2 turning of 7 day. - Consortium of bacteria, Fungi, Actinomycets and Mould were found after 2 days of application.

- MiCroBial bacteria have increased bio-degradation of organic matter.

Application of MiCroBial Odor on Windrow –

MiCroBial Odor Spraying

MiCroBial Growth of Solid Waste

Significant odor elimination ( No bad odor except humic smell) was observed on 2nd day of application which was absent on 7th day of application.

- Development of growth of fungi/mold/yeast and actinomycetes were seen after 2nd day of application. Further enhanced degradation of organic matter was seen during trial.( photo attached).

- MiCroBial Odor bacteria & enzymes has degraded complex molecules and convert into simple forms which can be easily taken up by other microbes like fungi, molds & yeast and enhanced their growth, increase in fungi growth is good for bio-degradation of fresh organic matter. So it can be concluded that MiCroBial Odor bacteria has enhanced other supportive microbes growth for bio degradation of organic matter.

- Sufficient growth of microbes were observed for better degradation of organic matter.

- Consortium of Yeast/molds & Actinomycetes Layer of MiCroBial growth observed.

- Conclusion – As per the results it can be concluded that MiCroBial Odor is helpful to control odor from solid waste and enhance degradation of organic matter in compost and solid waste.

Conclusion – As per the results it can be concluded that MiCroBial Odor is helpful to control odor from solid waste and enhance degradation of organic matter in compost and solid waste.

Contact

Satish Bhandare – Microbiologist

MiCroBial Technologies

Tel – +91 8888885375

Email – satish@microbialtech.com